Written by Gimmy

08 Mar 2015

I mentioned Chalmers workshop last time. Today, I’ll say a few words about students that are running wild in the CNC workshop.

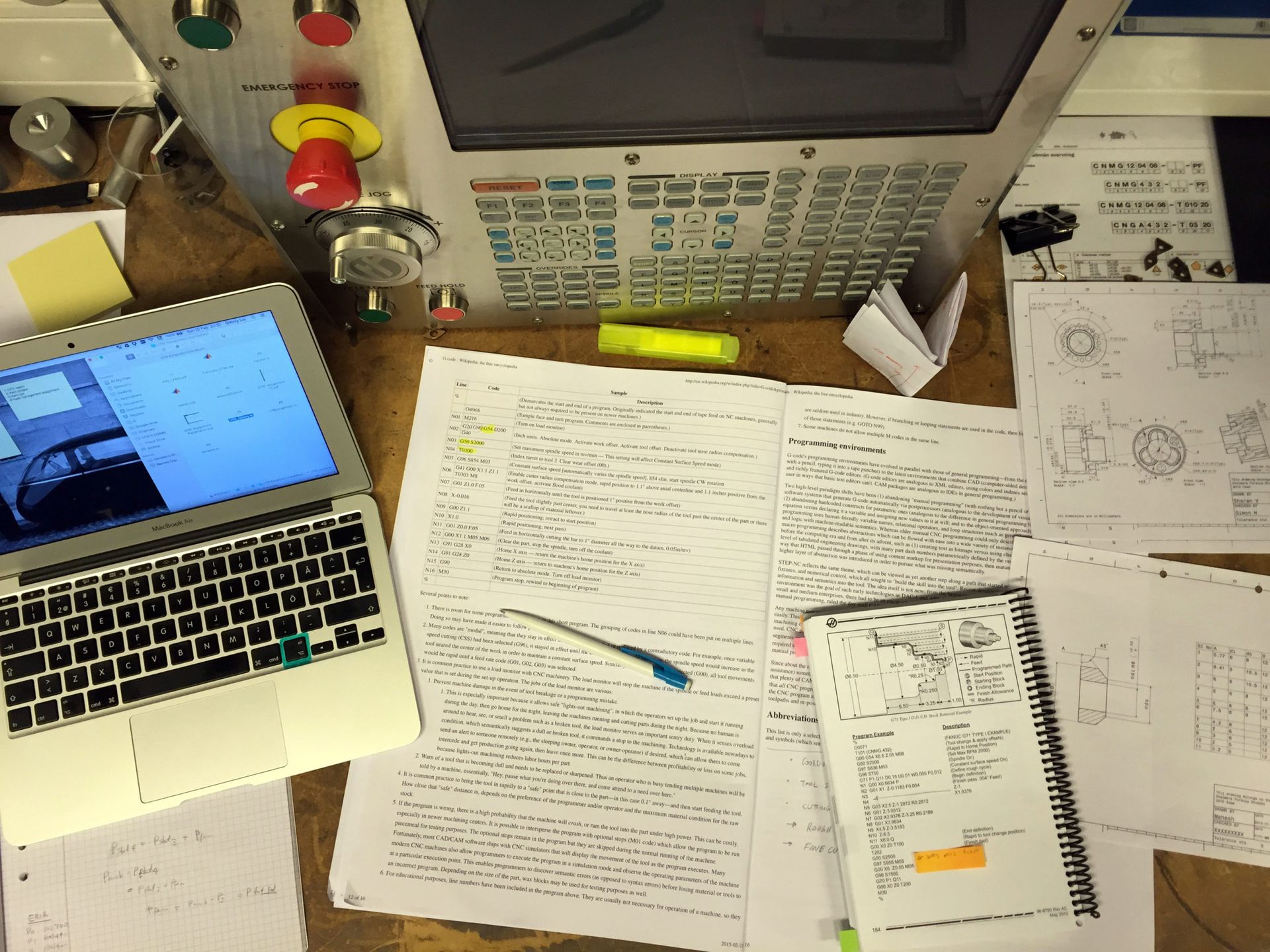

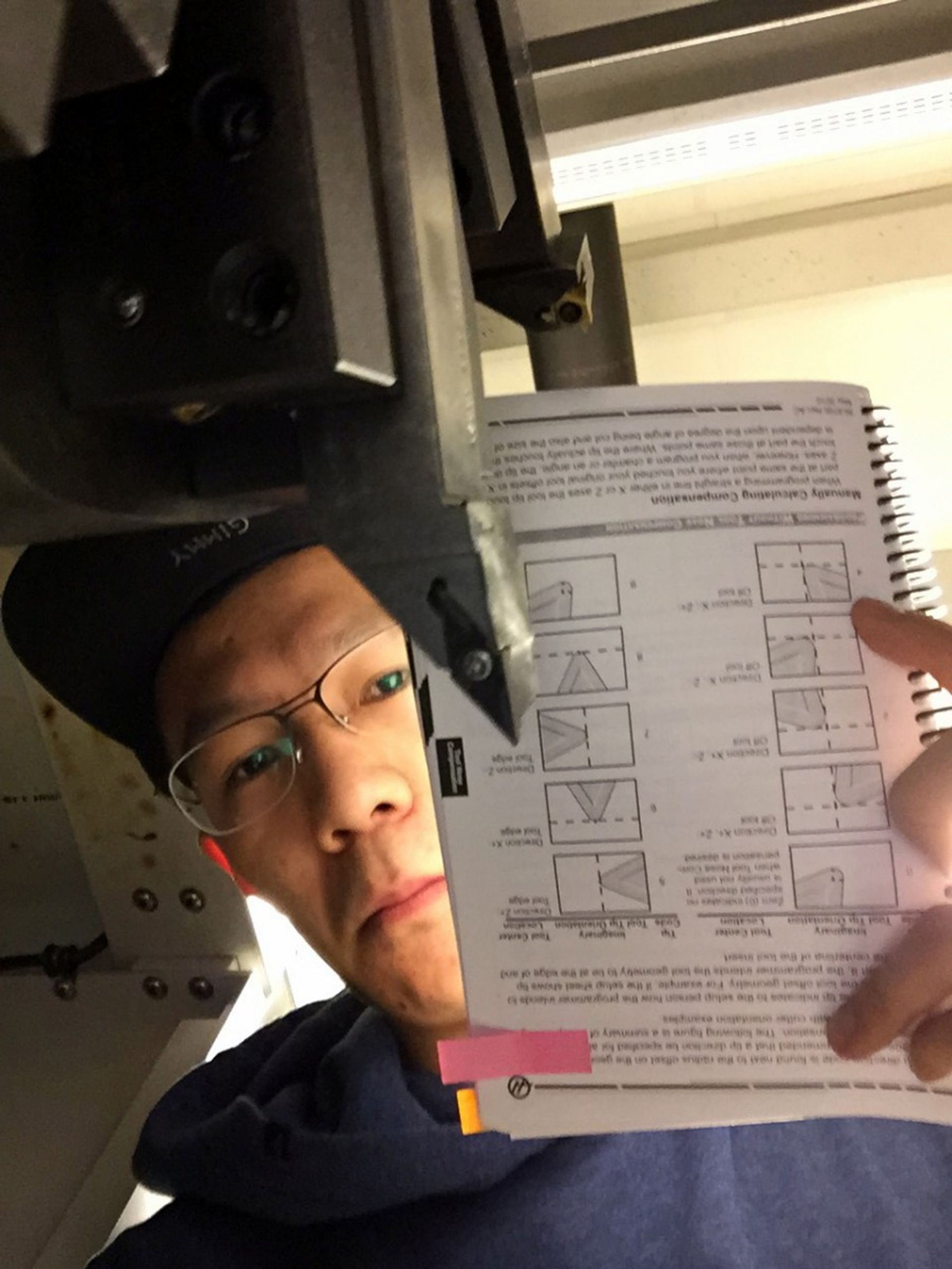

(photo: I am learning how to write G-Code on the CNC lathe machines)

Yes, students operating CNC machines. CNC stands for Computer Numeric Control. You are probably not so impressed, if you have no idea about CNC machines.

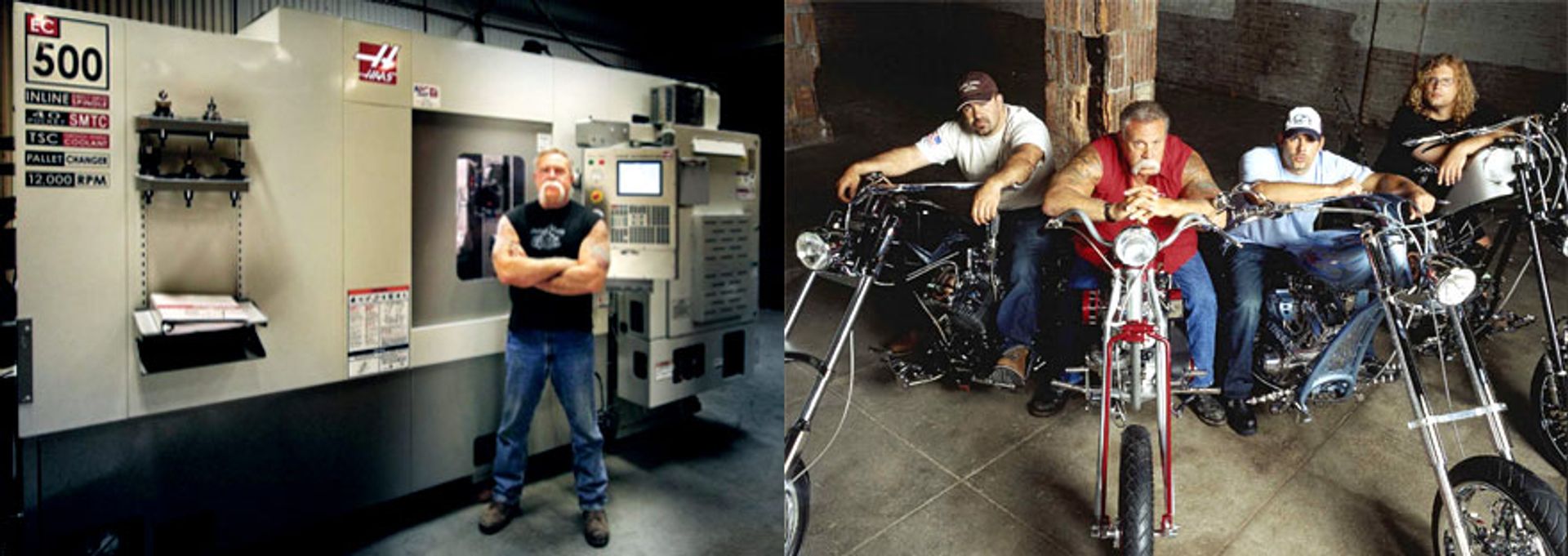

- They are freaking expensive (an inexpensive HAAS lathe costs about half a million SEK, or $100,000 USD)

- They aren’t easy to operate (people go through three years of college training)

- It is really easy to screw up the machine (if you clash two moving components, you will hear the loudest bang in your life…and then your wallet shrinks into a black hole)

- A nice Sandvik Coromant carbide tool cost 10,000 SEK, and it breaks easily when misused.

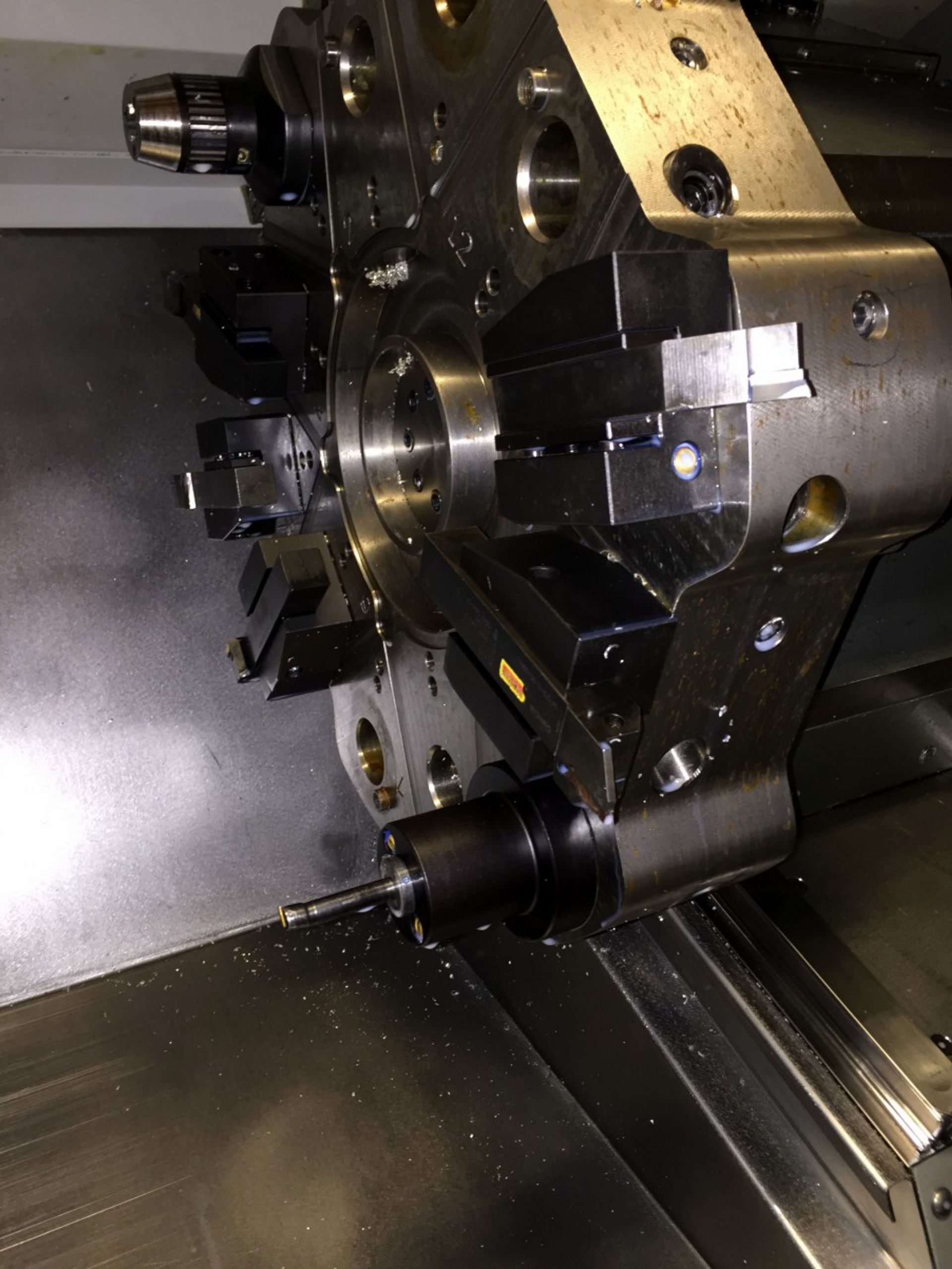

Photo: a typical CNC milling machine.

Ok, the students are not running “wild” in the “irresponsible” sense. They are operating the machine at its performance ceilings (meaning the machinists know what they are doing).

Photo: Niklas & Marcus on the CNC lathe.

I have never seen & heard a lathe running at 5000 revolutions per second. It sounds like an aircraft engine. Not exaggerating.

Of course, not anyone is allowed to fool around with these machines. The Chalmers Formula Student (CFS) machinists operating these CNC machines are extremely talented.

Photo: Göran from Sandvik Coromant visiting the CFS team and showing Victor how to realise a tool’s full capability.

Let me list a few:

- Isak from CFS 2014: he is probably born inside a CNC machine. Even the engineer at Sandvik Coromant (a Swedish tooling manufacturer) is impressed by his knowledge and ability.

- Johannes from CFS 2015: he is probably born with a welding gun in his hand. After seeing him laying down a perfect bead of aluminium weld, he goes into the CNC lab and mills out quite complex geometries.

- Niklas from CFS 2014 is a man of the north. He is from Umeå, where the SI bloggers visited last year. He is so familiar with the CNC lathe that the machine shop head comes to him with questions. (The flat hierarchy in Sweden also means the student-teacher relationship is quite sincere).

Photo: Johannes tooling around the CNC mill

Lately, Niklas is investing a lot of his free time to teach CNC lathe to Marcus and I.

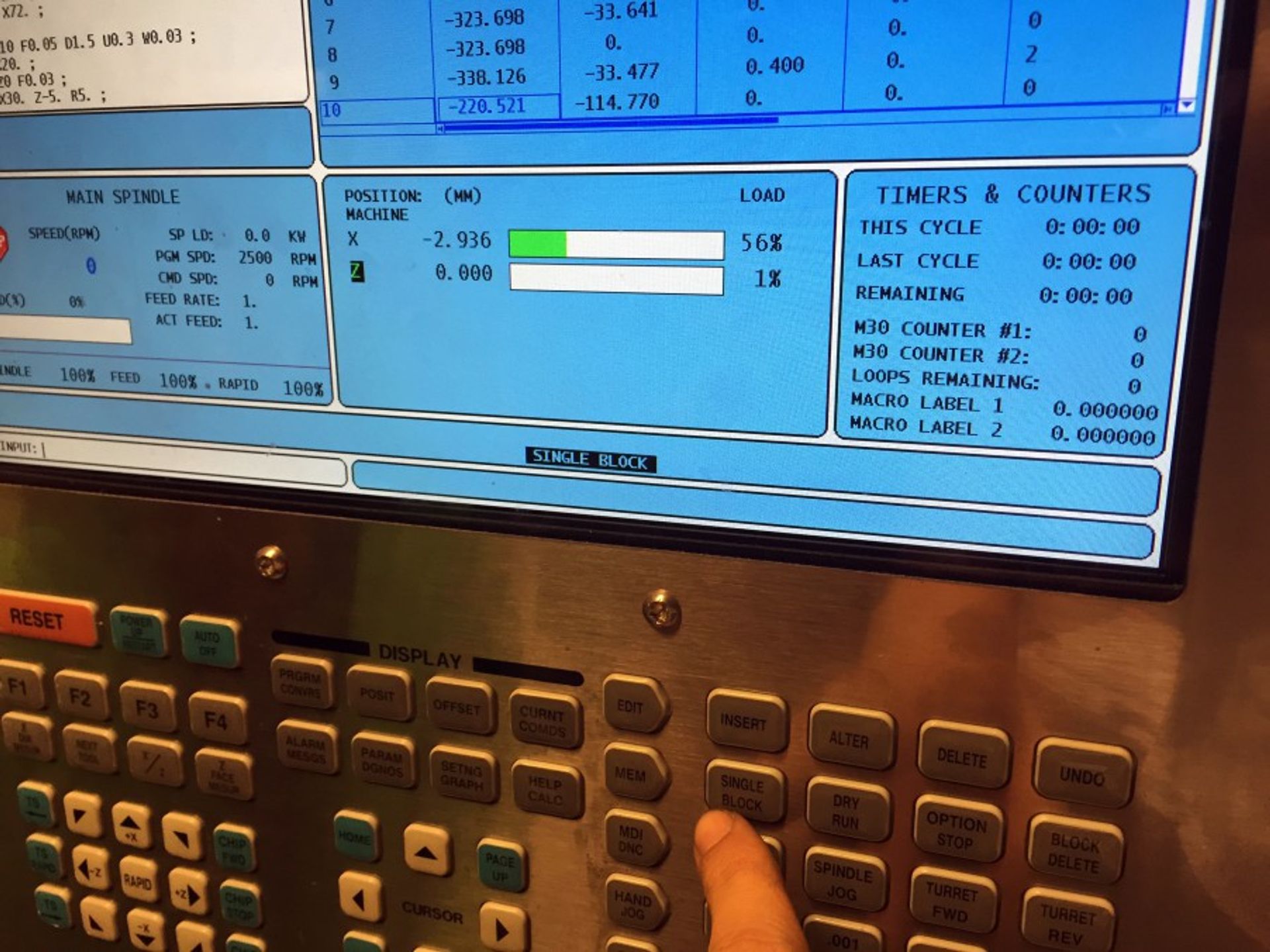

Photo: Carefully running the program in “single block” mode, baby steps, one block at a time.

I can’t fly on my own yet. I don’t think I will have time to practice enough on the CNC lathe to earn my “license”. Nonetheless, I feel quite privileged to touch the CNC machine and rev it up to 5000 RPM (under Niklas’ presence).

Photo: Trying to understand which tool goes where and does what…

Photo: Taking baby-steps, learning each tool and figuring out its “cutting position”. It’s not a selfie. I couldn’t determine the position of the tool that is oriented upside down…. position 3, matching?

Ok, back to the workshop.

Löv,

gimmygöteborg

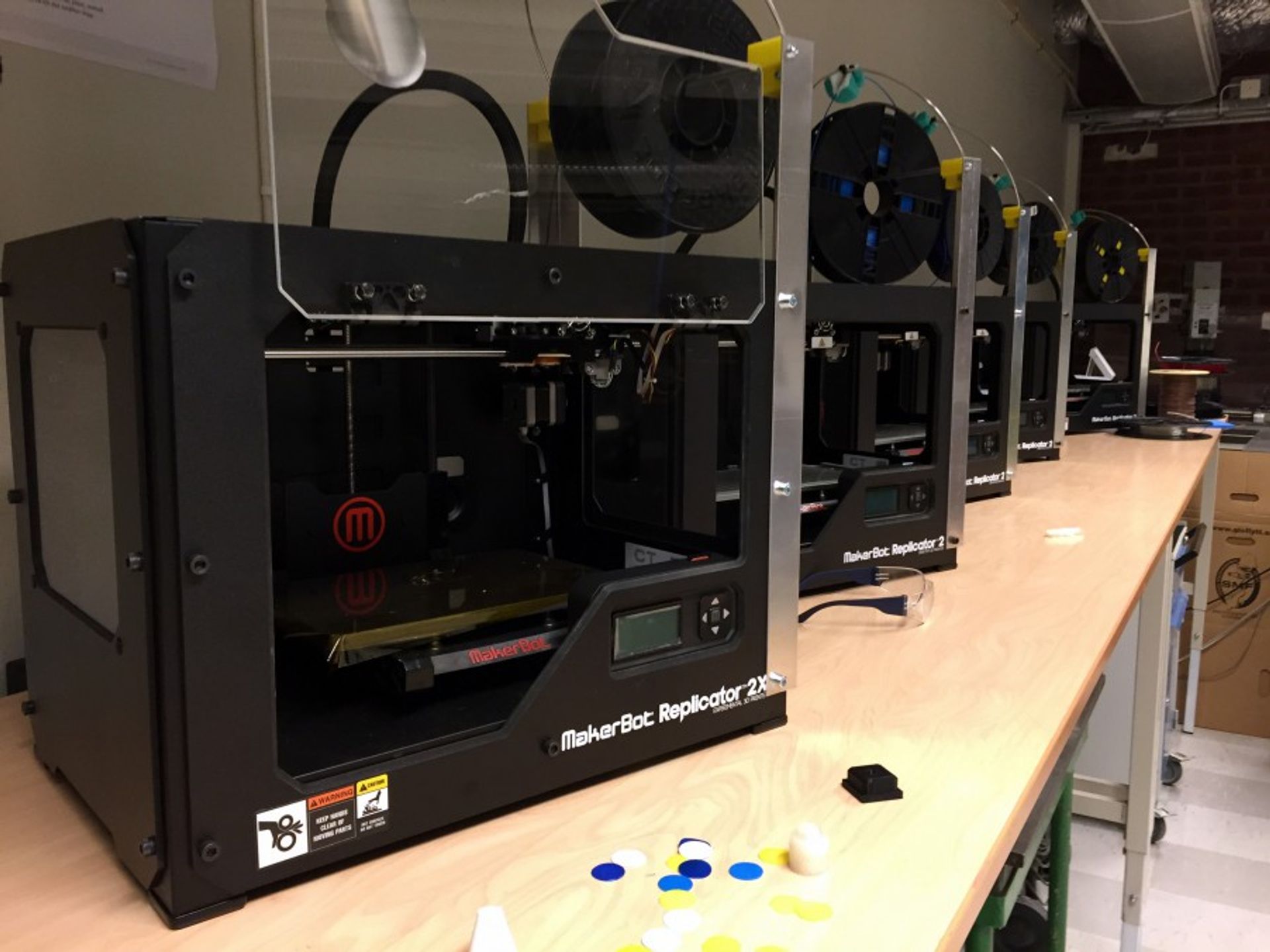

somebody is in charge of 3D printing… was it you Josue?